Quality

Inspection Tools & Measurement:We are equipped with essential testing and measuring instruments to verify critical dimensions and process conditions. Furthermore, we maintain standardized management and regular calibration of these tools to ensure the stability and consistency of inspection results.

system requirements to ensure product quality is both controllable and traceable.

-

CQC

CQC -

9001QMS

9001QMS -

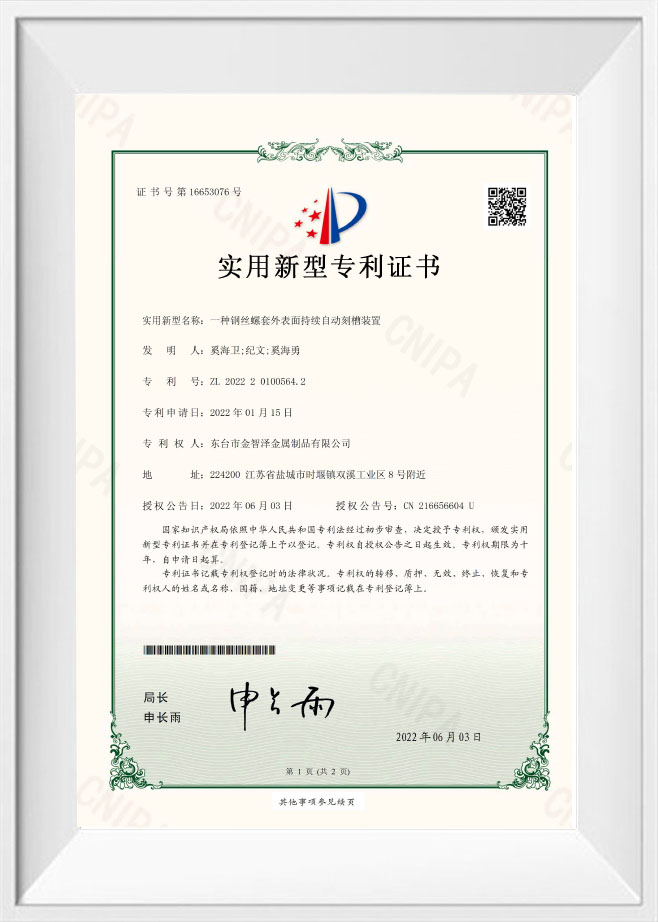

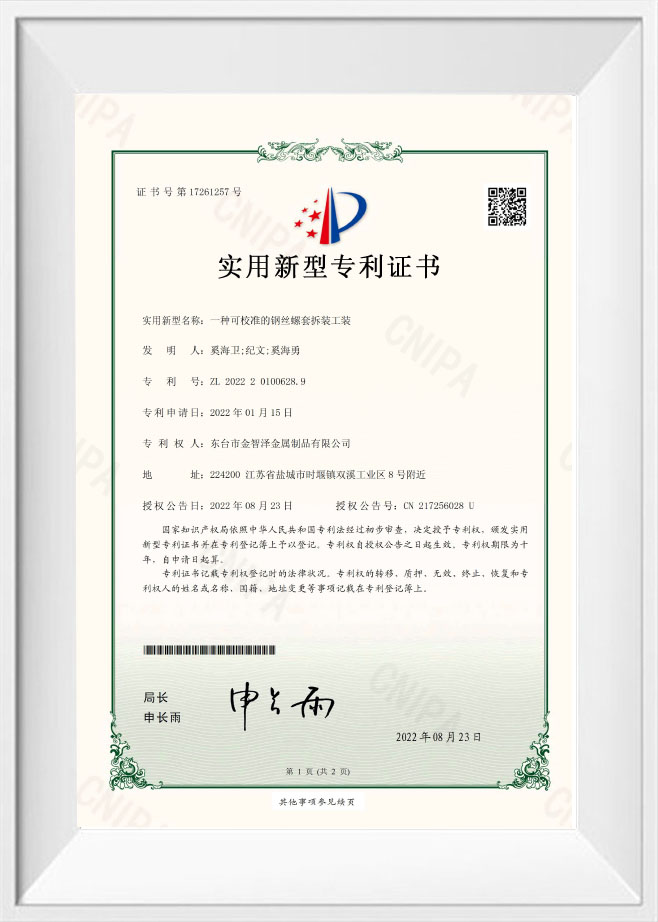

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate -

Utility Model Patent Certificate

Utility Model Patent Certificate

-

Materials are verified and inspected according to standards, with a focus on material quality, appearance, and critical dimensions. Only after confirming they meet production and application requirements do they enter the production process.

-

Key processes are equipped with control points that monitor thread conditions, critical dimensions, surface status, and assembly consistency. Anomalies are reported immediately and corrected to prevent defects from advancing to subsequent stages.

-

Before shipment, we conduct a final review of appearance, dimensions, packaging, and labeling. This ensures accurate model numbers, batches, and quantities, along with adequate product protection, fully meeting customer acceptance and usage requirements.

English

English